Every home has its own story of custom furniture

Ask anyone who’s just finished renovating, and chances are they’ll say: “Cut costs where you can—but never skimp on custom cabinetry.”

That’s because the way your cabinets fit, and how efficiently they use space, will affect your daily life for the next decade or more. Issues like excess formaldehyde, wardrobe doors that crack, gaps in cabinetry, or tatami mats that don’t quite fit—all of these can turn into constant headaches down the road.

Mistakes happen all the time in the custom furniture business, and for good reason—production, design, and installation are handled by different teams, who rely on old-school communication: phone calls and chat groups. With so many moving parts, errors are almost guaranteed.

Across China, hundreds of thousands of small companies keep up with the booming demand for custom furniture. But most of them still run on pen-and-paper management, where messy data and chaotic workflows are the norm.

For consumers, “custom” means a better experience. But for most factory owners, it means tougher management, higher costs, and greater risk.

The Hidden Struggles of Small Businesses

The custom furniture industry is far more complicated than most people realize.

For customers, it seems simple—just tell your designer what you want, wait a few weeks, and your new home takes shape.

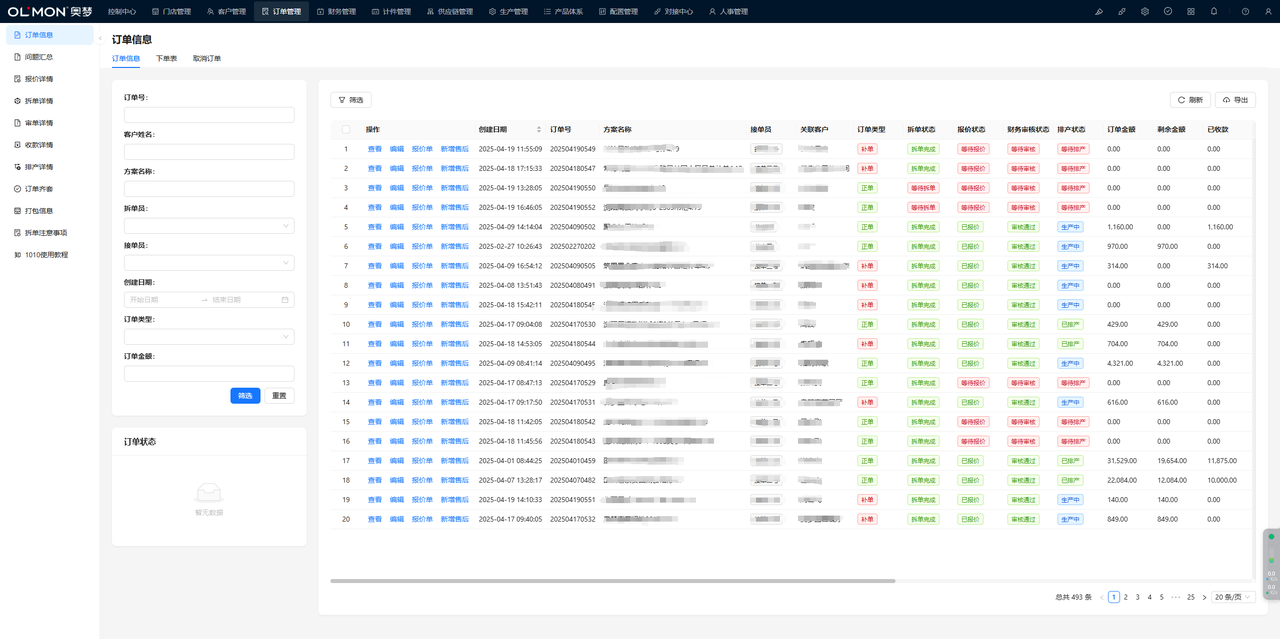

Behind the scenes, though, a single order can mean a dozen different steps: sourcing raw materials, cutting panels, scheduling production, arranging delivery, coordinating on-site installation, and handling after-sales support. At any point, something can go wrong—and when it does, the customer is quick to complain.

The challenge is even bigger in China, where over 90% of furniture makers are small or midsize businesses. Most don’t use proper digital systems. Instead, they manage everything through Excel spreadsheets, WeChat groups, or even handwritten notes. Design errors, lost work orders, mismatched accounts at month’s end—these are everyday headaches in a furniture factory.

OLMON Furniture is just one of hundreds of thousands of small custom furniture companies in China. Their team isn’t huge, but they serve plenty of customers every year—and for years, they faced all of these same issues, day in and day out.

They looked into buying ERP software or hiring outside vendors to help. But most solutions were either way too expensive, or simply didn’t fit their needs. Whenever they discussed requirements, the answer was always: “That’s not a standard feature. If you want customization, it’ll cost extra.”

“But our customers all have unique needs! Are we really supposed to pay every time we need the system changed?” For OLMON, this just didn’t make sense.

Building their own system was out of the question, too—hiring IT staff, buying servers, and ongoing maintenance would cost a fortune every year.

It’s not that they didn’t see the value of going digital—it’s that, for small businesses like theirs, the barriers were just too high.

How OLMON Furniture Found a New Way Forward

Everything changed when they discovered NocoBase.

Unlike traditional ERP systems, NocoBase is open source—which makes it much more affordable—and it uses a no-code approach, so even non-technical staff can build and manage the system. The promise of “building systems without writing code” gave OLMON Furniture a real sense of hope.

“It made them think: maybe this is worth a try.”

NocoBase stands out from the usual options—it isn’t as expensive or complicated as traditional coding frameworks, but it’s not as rigid or limited as most other no-code or low-code platforms. Instead, it combines the best of both worlds: all the flexibility of high-code, with the ease of no-code.

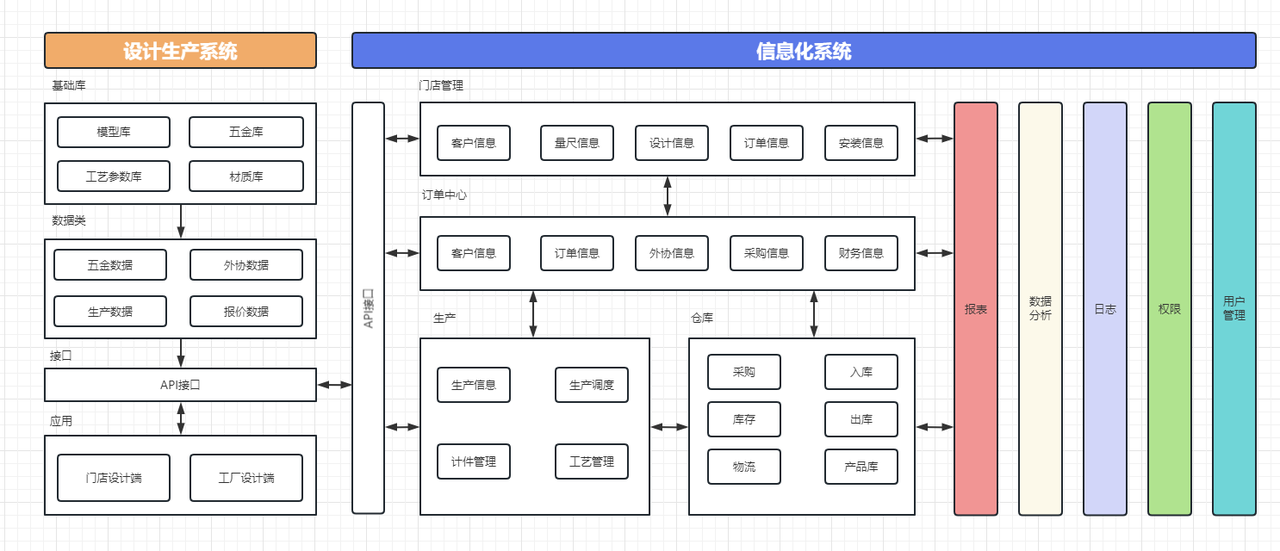

As OLMON Furniture dug deeper, they found several features that were a perfect fit for their business:

- Flexible, controllable costs.

NocoBase is open source, free to use, and supports self-hosting—no need to worry about expensive subscriptions or hidden fees. Pay only for the plugins you actually need.

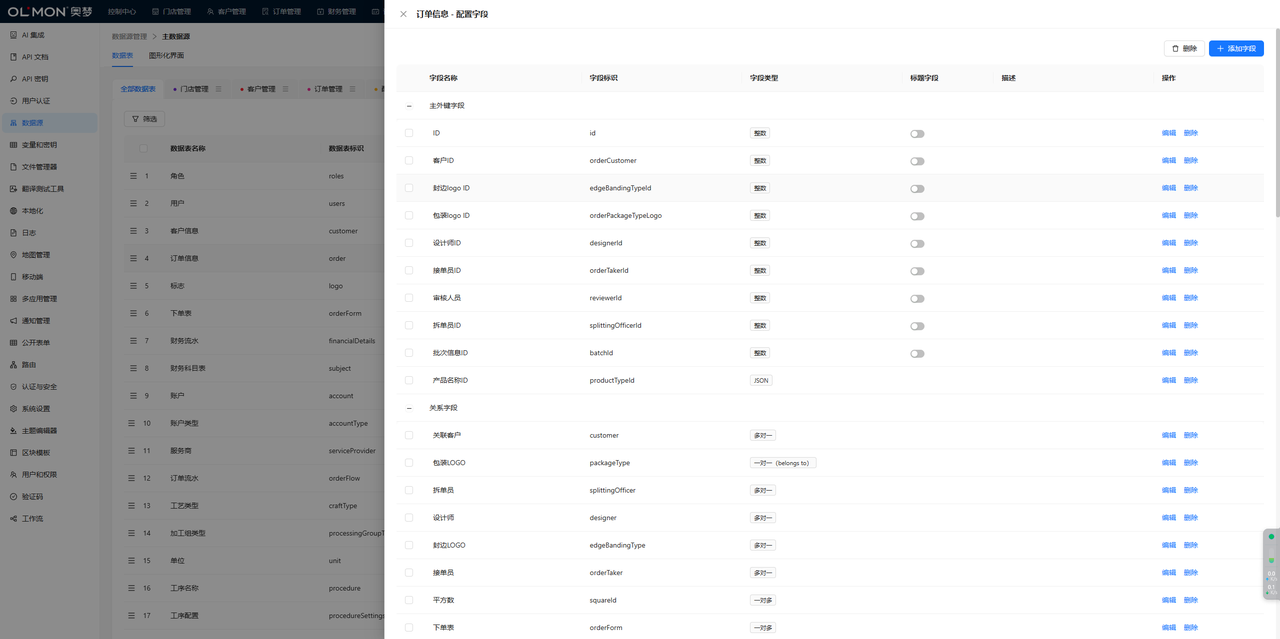

- Ultra-flexible data modeling.

All those tricky business rules—like managing multi-level relationships between customers, orders, and production schedules—can be handled through simple configurations. Complex structures like one-to-many or many-to-many relationships (including organizational hierarchies and permission systems) are easy to set up. You can even link directly to MySQL or PostgreSQL databases, with no need for endless data migrations.

- No-code setup, so business teams take the lead.

Instead of waiting for IT, business staff can now make changes themselves through a drag-and-drop interface. Workflows support multiple approval processes, and rule changes can be made nearly 90% faster. Dozens of built-in components make it easy to design interfaces for both desktop and mobile.

- Enterprise-grade data security.

With self-hosting, your core data stays physically separated from the cloud, solving the biggest data privacy concerns. Granular permissions—even down to a single field, like making order amounts visible only to specific roles—ensure sensitive data is protected.

- Limitless extensibility.

NocoBase’s unique microkernel architecture keeps the system lean (just 200KB at its core), so adding new features—like BI analytics—only takes a plugin. And with a thriving open-source community, there’s always a solution for any custom need.

ERP Isn’t Just for Big Companies Anymore

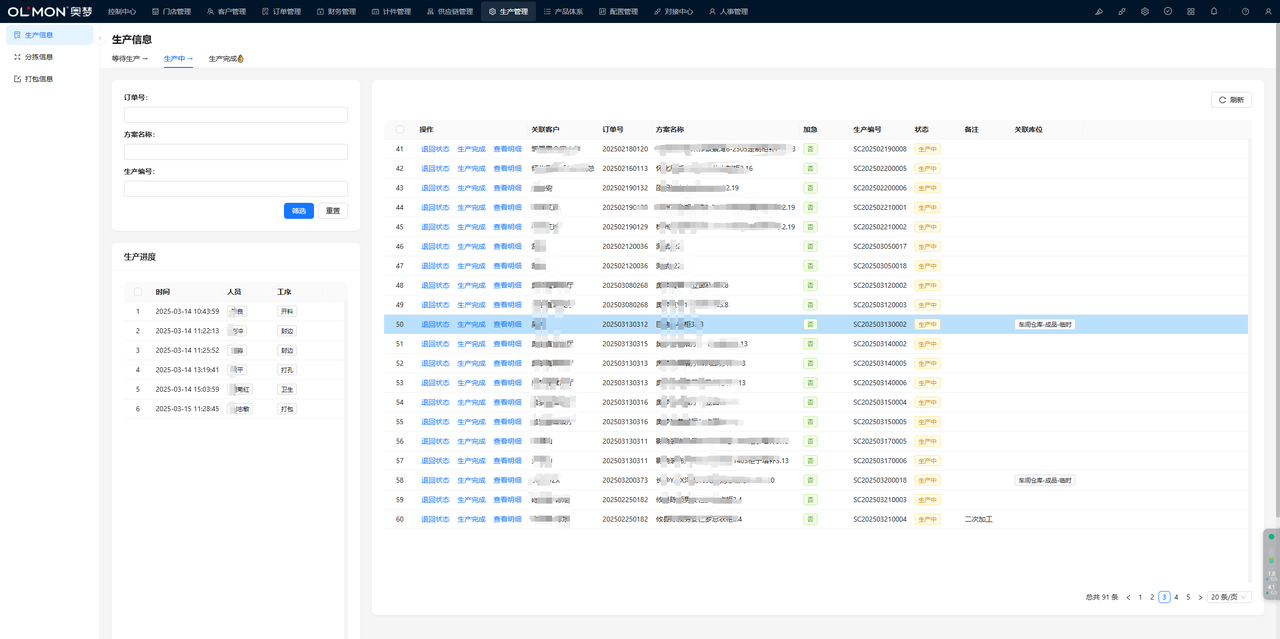

After OLMON Furniture adopted NocoBase, they gradually brought more and more of their operations onto the new digital platform. Two game-changing scenarios stood out—dynamic business rule configuration and real-time production data reconciliation.

Dynamic Rule Configuration: No More Painful Development Cycles

With traditional development, even the smallest change in business rules meant weeks of work for the tech team:

- Backend developers had to rewrite interface code late into the night.

- Frontend engineers scrambled to update React or Vue components.

- Database specialists nervously adjusted table structures and migrated old data.

- The whole process could drag on for two to three weeks. Any slip-ups meant growing technical debt, until eventually no one wanted to touch the codebase.

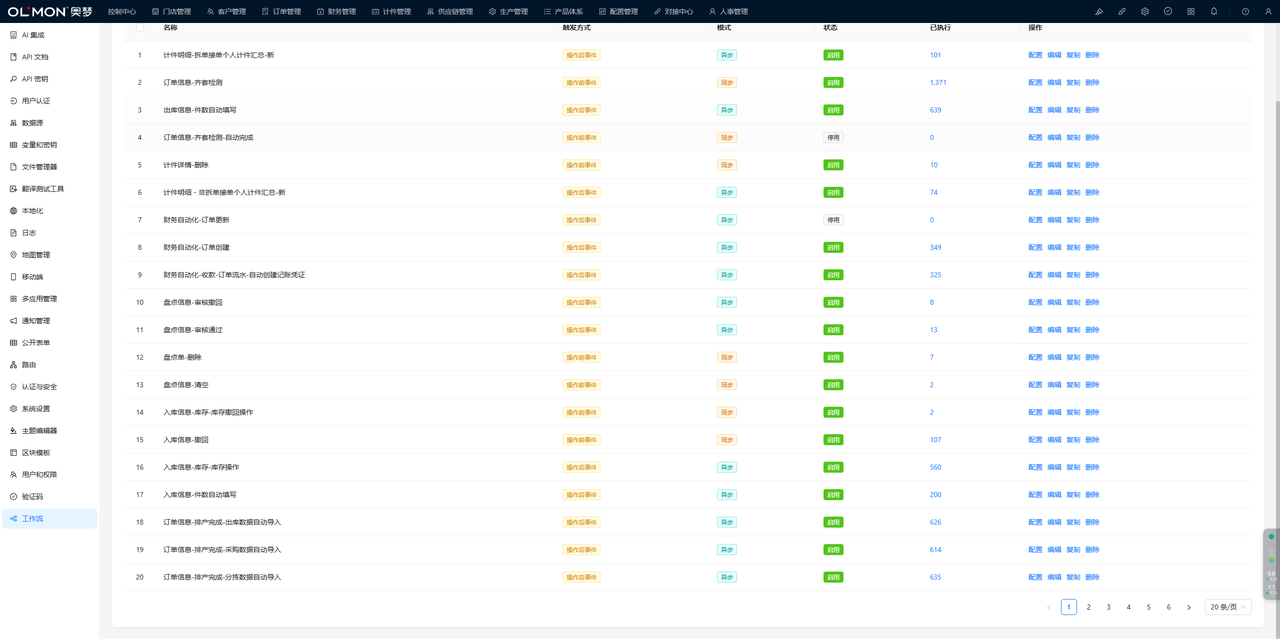

But with NocoBase, everything changed:

- Business teams can now update data models and business rules directly through an easy-to-use interface—new tables and APIs are generated automatically.

- What once took two days to add a field now takes just five seconds.

- Changing a form, which used to require three days of back-and-forth, is now done in ten minutes on the platform.

- Built-in workflow versioning makes it easy to track changes and avoid confusion.

Best of all, business users are now in the driver’s seat, while IT only needs to handle a few core extensions—their workload is drastically reduced.

Manual Reconciliation Is a Thing of the Past

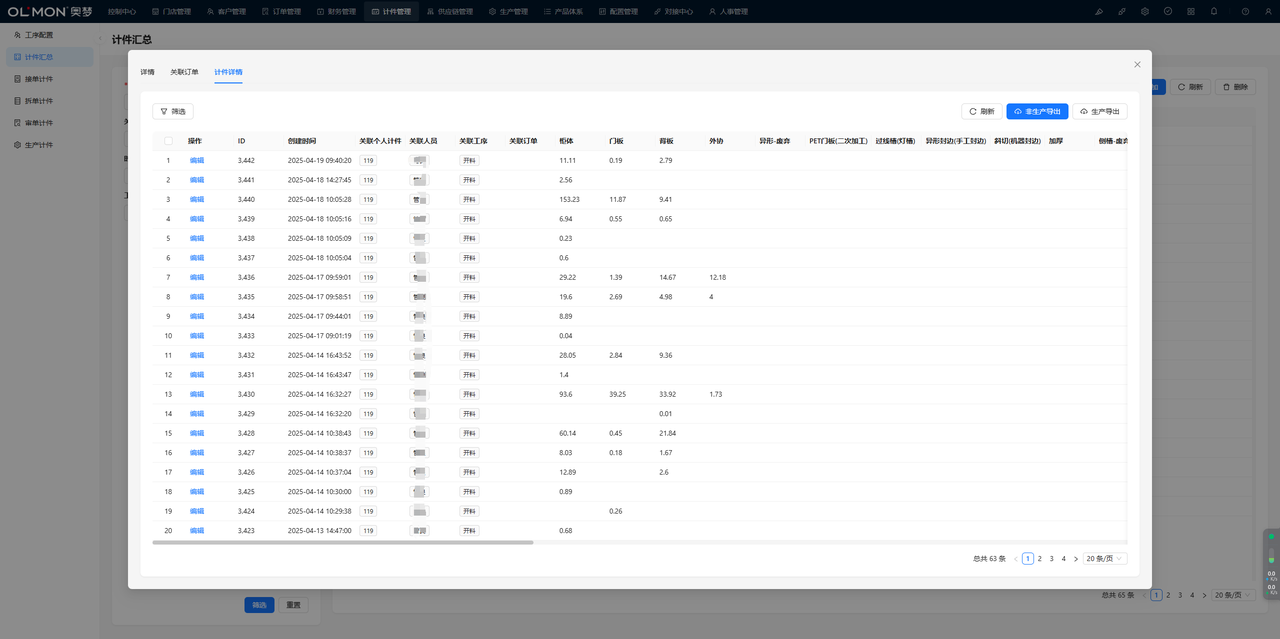

Piece-rate pay is common in the furniture business—but it’s also a major source of payroll disputes. OLMON Furniture used to manage payroll with paper slips and Excel sheets. Every month, five people on the finance team would work overtime for a full week to check records, yet errors still hovered around 20%, and pay disputes were routine.

To finally fix this, OLMON hooked up NocoBase to their shop floor barcode scanners and PDAs. Now, every time a worker completes a task, they scan and confirm it on the spot—data flows straight into the backend system for instant validation:

- If a worker scans the same code within ten minutes, the system spots the duplicate and blocks it.

- MES and finance data are now seamlessly connected, so production progress and payroll always stay in sync.

- Monthly reconciliation shrank from five people spending seven days to just one person in a few hours—with errors and pay disputes virtually eliminated.

Supervisors can now track real-time productivity rankings by the hour. If efficiency swings by more than 20%, the system automatically triggers an alert for a quick follow-up.

With integrations to Kingdee ERP and other platforms, multi-source data updates instantly, and financial documents are generated automatically—making finance management even smoother.

As for the workers? No more bugging finance for pay details—now they can check their daily earnings anytime, right from the company’s WeChat.

Let Data Speak

With the digital system fully in place, OLMON Furniture’s team saw firsthand that “efficiency” isn’t just a buzzword—it’s something they now experience every single day.

Problems that once seemed impossible to solve can now be tracked, measured, and resolved with clear, reliable data.

| Management Metrics | Before | After | Improvement |

|---|---|---|---|

| Rule adjustment time | 14 days | 2 hours | ↓98.5% |

| Data error rate | 12% | 0.30% | ↓97.5% |

| Manual labor cost | ¥50,000/mo | ¥5,000/mo | ↓90.0% |

| Customer complaint rate | 8% | 0.50% | ↓93.7% |

Behind it all is a total shift in how the company operates.

Data checks and reconciliations are more accurate than ever. The finance and management teams are freed from endless manual work, and customer service has reached a whole new level.

Most importantly, all these improvements came from within—driven by OLMON’s own staff, not costly outside consultants. The power to go digital is truly back in their own hands.

The True Future of Digitalization: Tools You Can Afford, and Tools That Really Work

For a long time, “digital transformation” and “ERP systems” belonged only to big companies. For countless traditional small businesses like OLMON Furniture, the high costs, complicated development, and drawn-out rollouts made digitalization feel totally out of reach.

But now, everything is different.

OLMON Furniture isn’t content with just “going digital”—they want to turn these new digital capabilities into a foundation for ongoing innovation and growth.

Looking ahead, their goals are clear:

- Deeper Technology

Build out industry-specific features with NocoBase’s plugin system—like automated order splitting and smart process scheduling—to fine-tune workflows for custom furniture.

- A Collaborative Ecosystem

Co-create a shared library of solutions for the home customization industry with the NocoBase community, driving standards and making it easier for more businesses to share experiences, learn, and grow together—no one has to go it alone.

- Industry Vision

Prove that even in industries as complex and ever-changing as custom furniture, you can achieve efficient, elegant management with open-source, no-code tools. Digital transformation shouldn’t be reserved for big companies—it should be within reach for every small business that’s serious about growth.

NocoBase empowers traditional businesses that once could only watch from the sidelines to finally build their own digital management systems—on their own terms. Our mission: make digitalization truly accessible, truly usable, and truly impactful for every business that’s ready to embrace change. Every company that puts care into its work deserves to experience the growth that comes from going digital.

Related reading:

- From Designer to Builder: L&A’s Digital Transformation with NocoBase

- How KIGLAND Scaled Custom Anime Mask Production with Open-Source Tools

- How a 400+ Lawyer Firm Streamlines Commission Management with NocoBase

- Rapid Development with NocoBase: Driving Digital Transformation in Construction

- Orchisky’s Smart Manufacturing Upgrade: Why They Chose NocoBase

- Why Nint Chose NocoBase: Best Practices for In-House Development Transformation