The Challenges of Intelligent Manufacturing: The Inevitable Trend of Digital Transformation

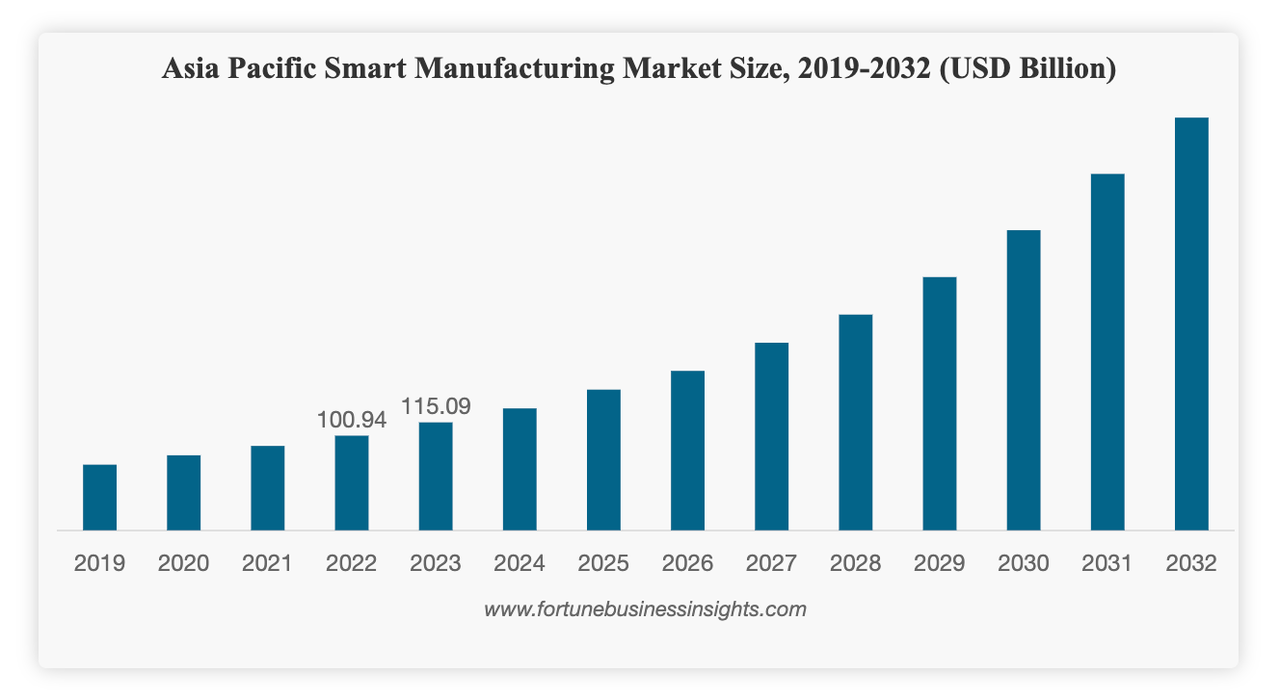

Under the global acceleration toward digitalization and intelligence in manufacturing, intelligent manufacturing has become a critical strategy for enhancing corporate competitiveness. According to data from Fortune Business Insights, the global intelligent manufacturing market reached 310.92 billion in 2023 and is projected to grow to $998.99 billion by 2032, with a compound annual growth rate (CAGR) of 14.0%.

This growth is driven by the widespread adoption of emerging technologies such as artificial intelligence, the Internet of Things (IoT), and big data.

However, digital transformation remains a significant challenge for many small and medium-sized manufacturing enterprises. Traditional enterprise management software often struggles to flexibly adapt to diverse business needs, while in-house system development entails high costs in time, labor, and technology. These hurdles create technical bottlenecks and management dilemmas for companies transitioning to intelligent manufacturing.

Jiangsu Orchisky Software Technology Co., Ltd. (hereinafter referred to as “Orchisky”) is a pioneer in providing intelligent solutions for manufacturers amid this industry landscape.

Orchisky: A Deep-rooted Informatization Service Provider for Manufacturing

Image source: Unsplash

Founded in 2004, Orchisky is a leading comprehensive informatization service provider in East China. The company specializes in intelligent manufacturing, offering one-stop digital factory solutions centered on informatization, digitalization, and intelligence to empower SMEs in achieving rapid digital transformation.

As a national-level pilot platform for SME digital transformation, Orchisky serves over 2,000 clients, including industry leaders such as Shanggong Shenbei, CGN, MEMMINGER-IRO, Wuyang Group, and maintains long-term partnerships with global giants like Microsoft, Siemens, and Hikvision.

Yet even for an experienced company like Orchisky, continuous optimization of its products and technical architecture has posed persistent challenges.

Challenges: Obstacles in Digital Factory System Development

As a one-stop smart factory solution provider, Orchisky’s software products span production management, supply chain optimization, equipment monitoring, and more. However, while addressing clients’ evolving customization needs, its development team faced three core challenges:

Challenge 1: Prolonged R&D Cycles, High Costs, and Difficulty in Agile Response

Orchisky’s software development process involved complex, highly customized workflows. From requirement analysis and coding to testing and delivery, each stage demanded significant time and labor. In the intelligent manufacturing sector, where clients’ management models vary widely, traditional development methods struggled to swiftly align systems with unique production workflows.

Challenge 2: Misaligned Requirements Leading to Rework and Cost Overruns

Building intelligent manufacturing systems required intricate business logic, and differing interpretations of requirements among developers often led to repeated revisions. This not only delayed progress but also increased labor costs. Additionally, as business expanded, developers faced mounting pressure to master new technical frameworks to meet diverse client demands.

Challenge 3: Project Delivery Delays Impacting Client Satisfaction

High technical complexity and communication costs caused frequent project delays, resulting in financial penalties and eroded client trust, potentially weakening Orchisky’s competitive edge.

To overcome these hurdles, Orchisky sought a more efficient and flexible development model to streamline R&D, reduce costs, and accelerate delivery. This led them to adopt NocoBase as their key technological solution.

Reshaping R&D with NocoBase

As an open-source, extensible no-code/low-code platform, NocoBase offers robust data modeling capabilities and a flexible plugin architecture, enabling Orchisky to rapidly build tailored management systems. By leveraging NocoBase, Orchisky revolutionized its software development approach for intelligent manufacturing systems:

✅ Shortened Development Cycles, Multiplied Efficiency

Traditional development required extensive coding, but NocoBase’s visual interface allowed developers to drag-and-drop components and configure parameters for rapid application assembly. Systems that once took months to develop could now be delivered in weeks, dramatically improving agility.

✅ Lowered Technical Barriers, Enhanced Team Collaboration

NocoBase not only enables professional developers to build applications more efficiently but also allows business personnel and product managers to be more deeply involved in the system-building process, promoting cross-team collaboration and improving overall development efficiency.

Under the traditional development model, companies often relied on senior engineers proficient in programming languages such as Java and Python. NocoBase provides visual data modeling and application-building tools, allowing developers to focus more on optimizing and innovating business logic, reducing the burden of basic coding. This not only accelerates system delivery but also helps companies allocate technical resources more reasonably, enabling the R&D team to devote more energy to high-value innovation projects.

✅ Component Reusability, Minimized Redundancy

NocoBase’s highly reusable plugin architecture allows companies to expand based on existing modules, avoiding redundant development and improving development efficiency. For example, when building a new manufacturing enterprise management system, Orchisky’s development team can directly reuse the previously built “production management” module, eliminating the need to start from scratch and significantly shortening the delivery time.

✅ Customization Flexibility, Elevated Client Satisfaction

The open-source nature of NocoBase enables Orchisky to provide highly flexible personalized customization capabilities to customers, more accurately matching the business needs of different enterprises.

The low-code feature of NocoBase not only reduces the development cycle but also allows Orchisky to respond more agilely to customer needs. Compared with traditional customized development models, system delivery speed has increased several times, significantly improving customer satisfaction.

NocoBase Empowers Orchisky to Accelerate Intelligent Manufacturing Innovation

Through in-depth cooperation with NocoBase, Orchisky has not only improved its own R&D efficiency but also helped more manufacturing enterprises accelerate their digital transformation. To date, nearly 10 customers have used the systems developed by Orchisky based on NocoBase. In the future, Orchisky will further leverage NocoBase’s flexible architecture and agile development capabilities to gradually replace the original intelligent factory source code development model, providing customers with more efficient and intelligent solutions.

This is not only a technological innovation but also a transformation of the digital upgrade model for manufacturing enterprises. From cumbersome code development to agile configuration, and from long delivery cycles to rapid deployment, Orchisky and NocoBase are exploring a more efficient and sustainable digital path for the manufacturing industry. In the future, Orchisky will continue to focus on the application of low-code technology in the field of intelligent manufacturing and join hands with more enterprises to step into the new digital era.

“Let technology serve business, and let innovation reach further.”

Related reading:

- Why Nint Chose NocoBase: Best Practices for In-House Development Transformation

- GemelSoft Enhances Internal Systems and Expands External Business Through NocoBase Integration

- The TEDxDUTH Transformation with NocoBase

- Sambruk Leverages NocoBase to Ensure Digital Learning Resources in Sweden Comply with GDPR

- Bestone Leverages NocoBase to Streamline Legal Case Processing to Improve Productivity

- Xiangcheng Records Leverages NocoBase to Drive Rapid Development in Smart Record Management